Well, here is a post with a bit of everything on it, with random pictures from my phone from this week so far.

Fouga nose-light testing - I had to drop the 6.6v from the LiFe to 6v max with a regulator as apparently the LED unit has a max voltage at that value. All programmed up now!

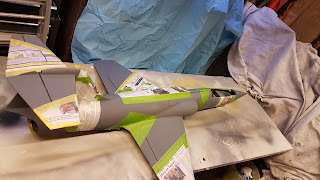

The mini A4 has been re-servo'ed, and also set up on the Horus.

A bit of surgery for the A4 - tail incidence change. This has now been blocked out with balsa and re-covered.

Fouga out in the sun after her satin lacquer top coat.

The little fatty! She took about 5 ounces of lead in the nose to balance.

All pile on the scales.

Fouga detail shot.

U2 on the c-of-g rig. Balanced between 5 and 8% stability.

Belly shot. I've taped up the retract doors for now, as the maiden will be without it.

Looking forward to some flying this weekend.